Our beautiful volcanic stone tables are hand-crafted in Deruta, Italy, a small medieval town famous for its traditional production of majolica ceramics. Here the secrets of the art of majolica have been passed down through the centuries from one generation to another, upholding the tradition of intense colors, exquisite design and high quality characteristic to this historic region. Each table is unique not only in the strokes of the artisan’s paintbrush but also in the very nature of the materials used to create these works of art.

Unlike common mosaic or an inlaid table, no glues, mortar or grout are used to manufacture these tables. The ceramic glaze is fired directly onto the surface of the solid slab of stone, sealing the tabletop completely and rendering it extremely sanitary and very easy to clean. In addition moisture cannot penetrate the stone surface and with freeze-thaw damage the table.

Due to the natural composition of the volcanic stone slight variations in its color and porous texture are to be expected. These natural imperfections combined with the weatherproof properties of the finish and the unique strokes of the artisan’s paintbrush render each tabletop an inimitable true masterpiece that will last a lifetime.

The process starts at the quarry and ends with the final inspection and shipping to your home!

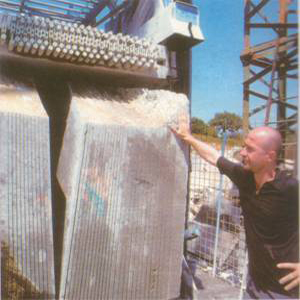

Quarry

Large stone blocks of “peperino”, a volcanic stone, are carved from an old quarry in Tuscany in central Italy. This stone has a high quartz content that makes it suitable for kiln firing.

Selection of Stone Slabs

Each block of volcanic stone is then cut into approximately 1 1/4 inch slabs. Only the most suitable stone slabs are selected and cut into the desired tabletop shapes.

First Kiln Firing

The tabletop edges are then bull-nosed before undergoing the first 24 hour firing “prima cottura”. During this process the color of the stone turns reddish. This firing makes sure the stone has no impurities and can withstand extreme temperatures.

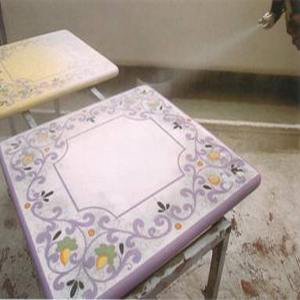

Hand Painting by Skilled Artisans

Next the tabletop is hand painted by artisans adopting the same techniques that have been used to create majolica ceramics since the Renaissance.

Second Kiln Firing

When the decorative painting has dried the tabletops are glazed and fired a second time “seconda cottura” for 24 hours thus obtaining a durable shiny majolica finish and the characteristic “crackled” look.

Final Inspection

The finished product is carefully inspected and securely crated for shipping.

Hand Forged Wrought Iron Table Bases

Our tablebases are hand-forged in Italy with top quality wrought-iron that has been galvanized with zinc to prevent rust and oxidation and then powder-coated in a graphite finish that can withstand low and high temperature variances for indoor or outdoor use. The galvanization and powder-coating process makes the iron highly chip and scratch resistant, eliminates sharp edges while providing resistance from many chemicals, petroleum and salt. Our ironwork has been tested to withstand 500 hours of direct saline mist. The galvanization process also provides electrical and thermal insulation therefore reducing the extreme cold or hot feeling of the metal. Galvanization protects from UV light and reduces fading. Each table base and chair is fitted with non-marking black nylon glides to add stability and protect floors. Quite simple to assemble these structures are solid and sturdy. The design of these tablebases is clean and simple. Much attention is paid to detail, some of which can be seen in the rust-resistant concealed welding and the solid brass fittings. Each table base is fitted with non-marking black nylon glides to add stability and protect floors.